01

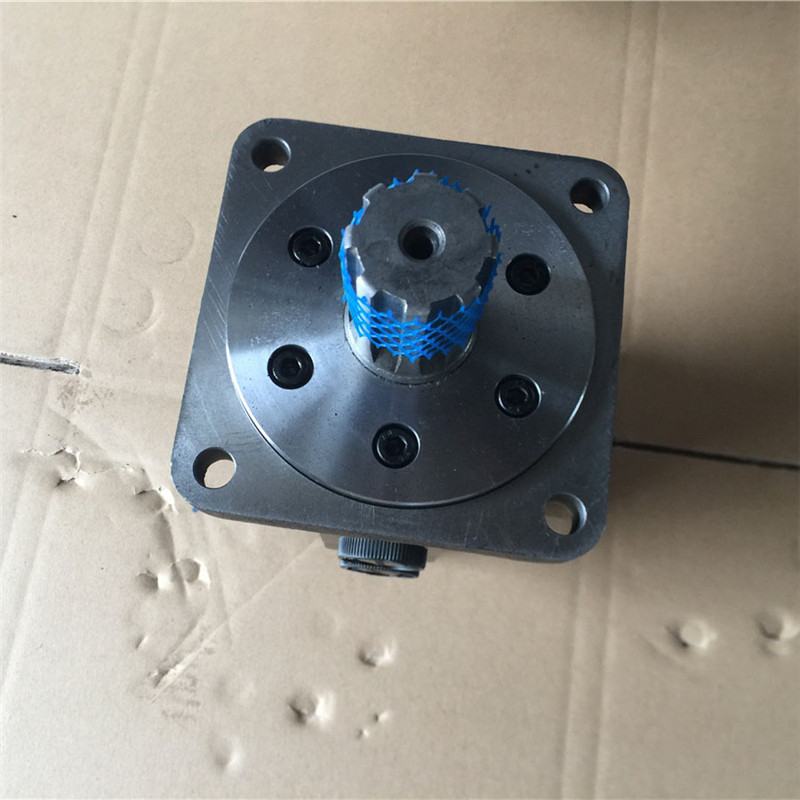

Series 51 Series 51-1 Bent Axis Variable Displacement Motors

04

7 Jan 2019

Series 51 and 51-1 variable displacement motors are bent axis design units, incorporating spherical pistons. These motors are designed primarily to be combined with other products in closed circuit systems to transfer and control hydraulic power. Series 51 and 51-1 motors have a large maximum / minimum displacement ratio (5:1) and high output speed capabilities. SAE, cartridge, and DIN flange configurations are available. A complete family of controls and regulators is available to fulfill the requirements of a wide range of applications.

Motors normally start at maximum displacement. This provides maximum starting torque for high acceleration. The controls may utilize internally supplied servo pressure. They may be overridden by a pressure compensator which functions when the motor is operating in motor and pump modes. A defeat option is available to disable the pressure compensator override when the motor is running in pump mode. The pressure compensator option features a low pressure rise (short ramp) to ensure optimal power utilization throughout the entire displacement range of the motor. The pressure compensator is also available as a stand-alone regulator.

04

7 Jan 2019

Temperature and viscosity requirements must be concurrently satisfied. The data shown in the tables assume petroleum-based fluids, are used. The high temperature limits apply at the hottest point in the transmission, which is normally the motor case drain. The system should generally be run at or below the rated temperature. The maximum temperature is based on material properties and should never be exceeded. Cold oil will generally not affect the durability of the transmission components, but it may affect the ability to flow oil and transmit power; therefore temperatures should remain 16 °C [30 °F] above the pour point of the hydraulic fluid.

The minimum temperature relates to the physical properties of component materials. For maximum unit efficiency and bearing life the fluid viscosity should remain in the recommended operating range. The minimum viscosity should be encountered only during brief occasions of maximum ambient temperature and severe duty cycle operation. The maximum viscosity should be encountered only at cold start. Heat exchangers should be sized to keep the fluid within these limits. Testing to verify that these temperature limits are not exceeded is recommended.