01

Radial piston motor MCR Series 30, 31, 32, 33 and 41

04

7 Jan 2019

The MCR is a hydraulic motor with pistons arranged radially within a rotary group. It is a low-speed, high torque motor which operates according to the multiple stroke principle and delivers torque directly to the output shaft. MCR motors can be used both in open and closed circuits.

In the open circuit, the hydraulic fluid flows from the reservoir to the hydraulic pump from where it is transported to the hydraulic motor. From the hydraulic motor, the hydraulic fluid flows directly back to the reservoir. The output direction of rotation of the hydraulic motor can be changed, e.g. by a directional valve.

In the closed circuit, the hydraulic fluid flows from the hydraulic pump to the hydraulic motor and from there directly back to the hydraulic pump. The output direction of rotation of the hydraulic motor is changed, e.g. by reversing the flow direction in the hydraulic pump. Closed circuits are generally used for hydrostatic transmission in mobile applications.

04

7 Jan 2019

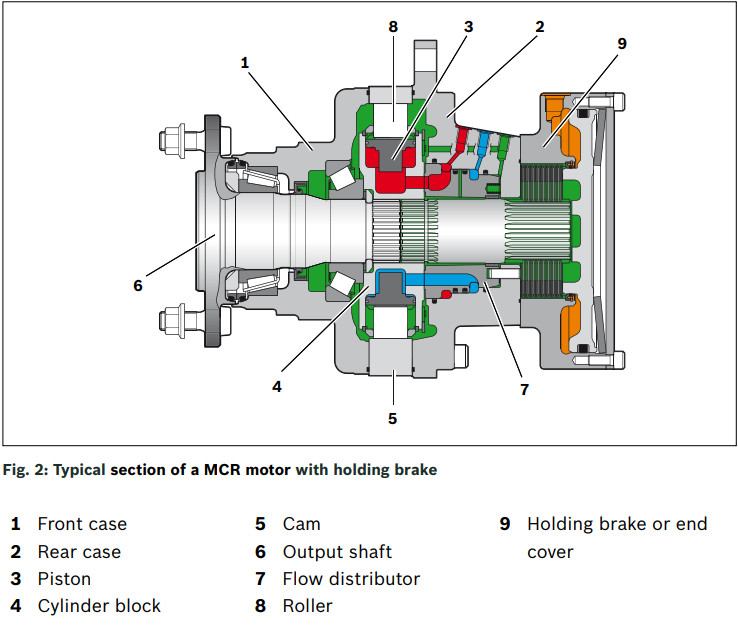

A radial piston motor consists of a two part housing (1, 2), rotary group (3, 4), cam (5), output shaft (6) and flow distributor (7).

It converts hydrostatic energy into mechanical energy.

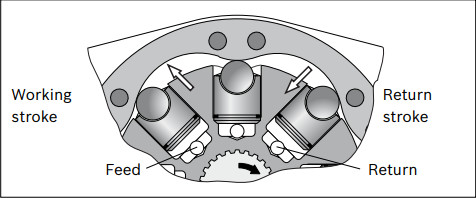

Hydraulic fluid is directed from the motor inlet port in the rear case (2) via the flow distributor (7) through galleries to the cylinder block (4). Pressure increases in the cylinder bore which forces the radially arranged pistons (3) outwards. This radial force acts via the rollers (8) against the profile on the cam ring (5) to create a rotary torque. This torque is transferred to the output shaft (6) via the splines in the cylinder block (4).

If the torque exceeds the shaft load, the cylinder block turns, causing the pistons to stroke (working stroke). Once the end of a stroke is reached the piston is returned to its bore by the reaction force at the cam (return stroke) and the fluid is fed to the motor outlet port in the rear case.

The output torque is produced by the force resulting from the pressure and piston surface. It increases with the pressure difference between the high- and low-pressure side.

The output speed depends on the displacement and is proportional to the inward flow. The number of working and return strokes corresponds to the number of lobes on the cam multiplied by the number of pistons.

04

7 Jan 2019

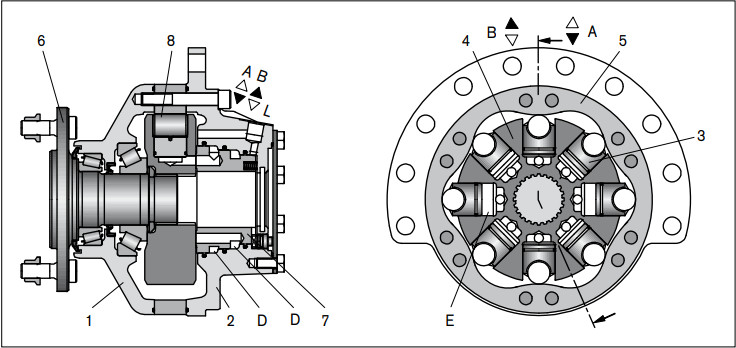

The cylinder chambers (E) are connected to ports A and B via the axial bores and the annular passages (D).

Tapered roller bearings capable of transmitting high axial and radial forces are fitted as standard, except on Hydrobase motors (half motor without front case).

In certain applications there may be a requirement to freewheel the motor. This may be achieved by connecting ports A and B to zero pressure and simultaneously applying a pressure of 2 bar to the housing through port L. In this condition, the pistons are forced into the cylinder block which forces the rollers to lose contact with the cam thus allowing free rotation of the shaft.

In mobile applications where vehicles are required to operate at high speed with low motor loads, the motor can be switched to a low-torque and high-speed mode. This is achieved by operating an integrated valve which directs hydraulic fluid to only one half of the motor while continuously re-circulating the fluid in the other half. This "reduced displacement" mode reduces the flow required for a given speed and gives the potential for cost and efficiency improvements. The motor maximum speed remains unchanged.

Rexroth has developed a special spool valve to allow smooth switching to reduced displacement whilst on the move. This is known as "soft-shift" and is a standard feature of 2W motors. The spool valve requires either an additional sequence valve or electro-proportional control to operate in "soft-shift" mode.